36V or 48V Systems

Motor

Our boat has a model BU5-4001 36V DC series motor, likely manufactured by Nidec/Tennant/Advance. It is a common motor, but Duffy removed the manufacturer name place and installed their own, making it difficult to know the specifications.

Some motors are designed to operate in a range of voltages, so you may not need to replace your motor if upgrading from a 36V to 48V system.

Inspection and Testing

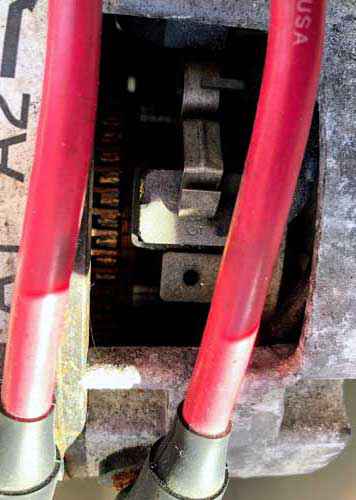

Brush and Commutator

The motor has four brushes that will eventually wear out. They rest upon the commutator, which should wear evenly, but much slower than the brushes.

Check for excessive sparking in the brush area or unusual noises. The motor may also operate intermittently or there may be a decrease in motor power. There are other causes of intermittent operation besides motor issues.

Inspection

Ensure that it is not possible for the motor to receive power.

Flip open the clip to loosen the metal cage covering the brushes and commutator, then remove

it to expose the brushes.

- The brush holders should be free of corrosion that may prevent the brushes from moving freely. The brush holders should not be damaged or melted.

- A spring rests on each brush, forcing it against the commutator. Each spring should be well aligned on the brush so that it provides even force.

- There should be ample brush material and the brushes should not be cracked.

- Inspect the commutator for abnormal wear. The commutator should be worn evenly with no significant ridges. The area should be free of debris and excess dust from brush wear.

Reinstall the cage, ensuring that it is clear of electrical terminals.

Mechanical Test

The motor should turn freely by hand with no grinding sound or feeling that could indicate a bad bearing.

Continuity Testing

-

With all power cables disconnected:

- There should be continuity between the two armature terminals (A1 and A2) and between the two stator or field terminals (S1 and S2)

- There should not be continuity between the armature and the metal motor case or between the stator and the metal motor case

- There should not be continuity between A1 and S2

Power Test

With the motor secured so it can operate, connect a 12V car battery as follows:- +12V to S1

- -12V to A2

- Jumper cable between A1 and S2

The motor should run, but slowly since you are only providing 12V.

Repair or Replacement

Motor rebuild or golf cart repair shops can rebuild your motor.

Eurton Electric

in Whittier, CA rebuilds Duffy motors and may

be a good source for parts.

in Whittier, CA rebuilds Duffy motors and may

be a good source for parts.

D&D Motor Systems

in Syracuse, NY offers modern replacements

for Duffy motors and motor controllers.

in Syracuse, NY offers modern replacements

for Duffy motors and motor controllers.